DESCRIPTION

The TL Series Telescopic Automatic Door is specifically designed for high-performance operation in heavy foot traffic environments, such as commercial buildings, airports, and hospitals. Featuring an advanced telescopic sliding door mechanism, the rear leaves move at half the speed of the front leaves, delivering a smooth, silent, and perfectly synchronized motion. This intelligent motion allows the door to open up to two-thirds of the total installation width, maximizing accessibility and making it ideal for wide automatic entrances.

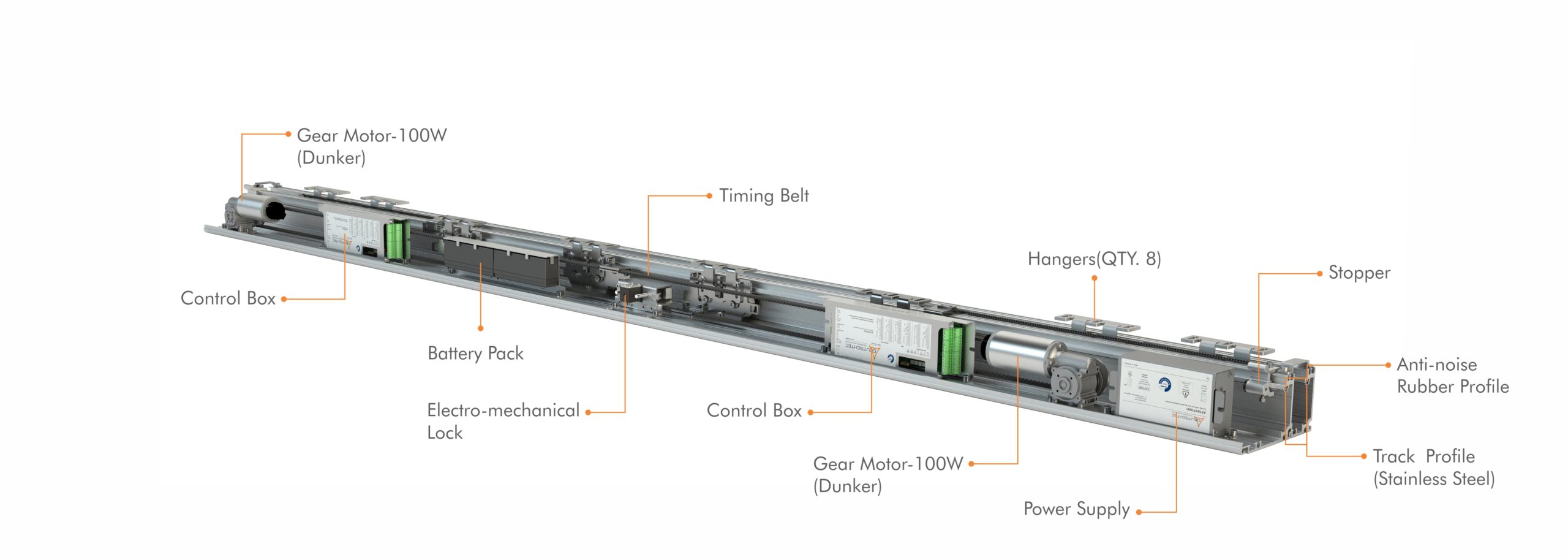

Tested for over one million open-close cycles, the TL Series ensures exceptional durability, long-term reliability, and minimal maintenance. In addition, the TL240ES is provided to highest levels of safety in escape routes. making it fully compliant with emergency exit requirements and modern building safety standards. This advanced system uses dual gear motors and controllers-one(slave) for opening cycles and the other (master) for closing cycles. In the event of an emergency, both motor sets are capable of opening the door, guaranteeing a reliable and swift exit.

Whether installed in a busy retail environment, healthcare facility, or transport hub, the TL Series guarantees safe, efficient, and uninterrupted access—even during emergency situations.

| Standards | TL240ES |

| DIN18650 | |

| EN16005 | |

| EN60335 | |

| EN ISO 13849 | |

| EU low voltage directives | |

| EU EMC directives | |

| ISO 9001 | |

| TÜV approved | |

| CE conformity | |

| 1.000.000 cycles durability test | |

| Technical Data | |

| Opening width – double leaves | 900 – 3000mm |

| Opening width – four leaves | 1800 – 4000mm |

| Max leaf weight, double | 2 x 150kg |

| Max leaf weight, four | 4 x 100kg |

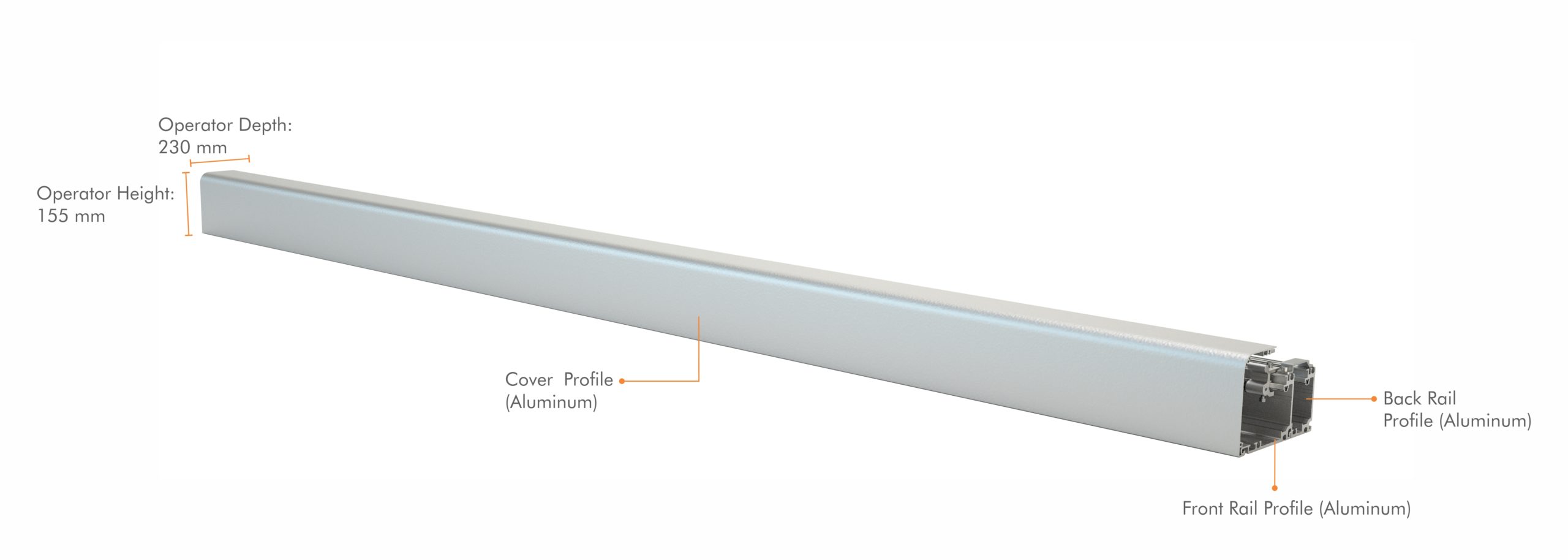

| Operator height | 155mm |

| Operator depth | 226mm |

| Opening speed | Variable up to 1.1 m/s

(Four leaves) |

| Closing speed | Variable up to 1.1 m/s

(Four leaves) |

| Hold-open time | 0 – 30s |

| Ambient temperature | -15 to +50°C |

| Protection class | IP20 |

| 100% German-made operator kit | |

| Control unit origin | Leesys GmbH, a part of Siemens Enterprise Communication |

| Gear motor origin | Germany |

| Track profile | Stainless Steel |

| Anti-noise rubber profile | |

| Gear motor power | 100W |

| Dual gear motor and control unit set for master and slave concept | |

| No. of hanger per leaf | 2 |

| External protected power supply | |

| Power supply power | 230V/33V,50VA(Peak 120VA) |

| Back-up battery for emergency opening | |

| Possibility to use safety sensors with testing signal | |

| 24V DC output for external accessories | |

| Power lock | |

| Lock monitoring | |

| Possibility of using more software and hardware options by using DEAP device (optional) | |

| Read-out error memory with error codes (with digital programme switch) | |

| Programmable output (optional) | |

| Programmable input (optional) | |

| Possibility of using mechanical key switch | |

| Possibility of using Digital programme switch (optional) | |

| Possibility of using electro-mechanical lock (optional) | |

| Possibility of using Battery | |

| Maximum operation cycles with 2.2 Ah backup battery | 400 |

| Maximum operation cycles with 7.2 Ah backup battery | 1000 |

| Frames | |

| Thermal break THB | |

| Thermal break TBS | |

| UTS | |

| Saturn | — |

| Frameless | — |